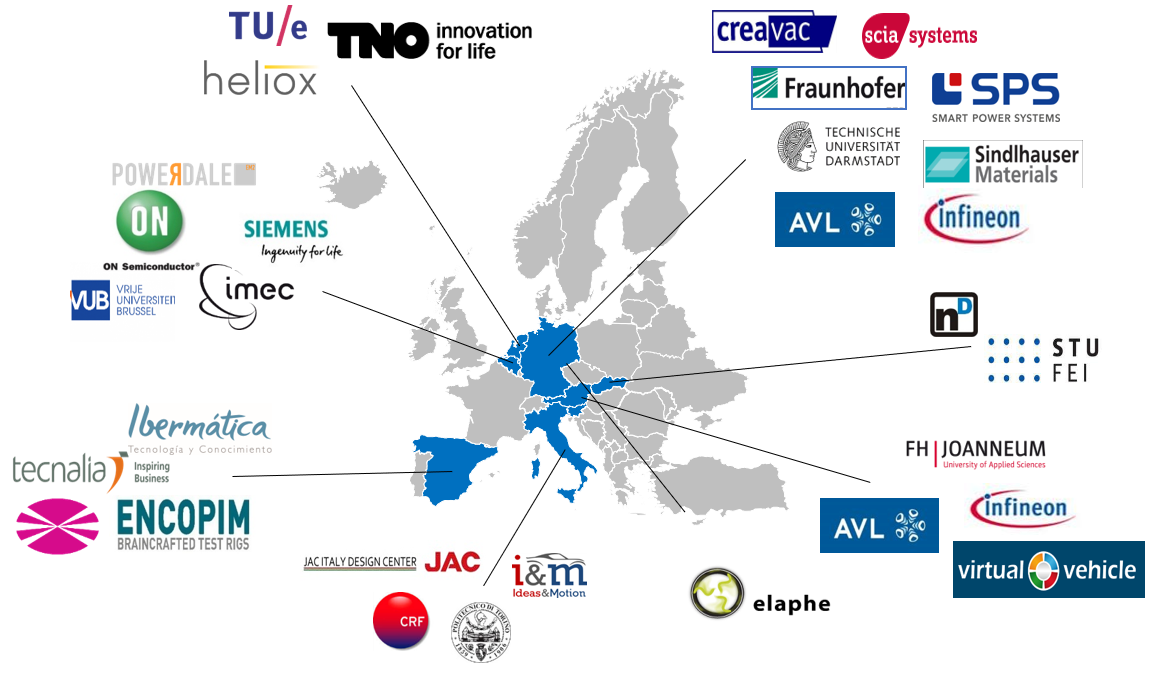

PROjECT PARTNERS

AVL List GmbH

AVL is the world's largest independent company for development, simulation, and testing technology of powertrains (hybrid, combustion engines, transmission, electric drive, batteries and software) for passenger cars, trucks, and large engines. AVL is acting in the following scope of business: Development of Powertrain Systems, Simulation, Engine Instrumentation and Test Systems.

COMPANY DESCRIPTION

AVL´s Powertrain Engineering (PTE) division activities are focused on the research, design and development of various powertrains – including all kinds of e-drivetrains – in the view of low fuel consumption, low emission, low noise and improved driveability.

The Advanced Simulation Technologies (AST) division develops and markets the simulation methods which are necessary for the powertrain development work.

The Instrumentation and Test Systems (ITS) division is an established manufacturer and provider of instruments and systems for powertrain and vehicle testing including diagnostic sensors, complete engine, powertrain and vehicle test beds. This includes the development of test systems for batteries, inverters, and e-motors.

ROLE & KEY CONTRIBUTION

AVL is acting as the project coordinator of the HiPERFORM project and additionally is the leader of Use-Case 1 - Test system concepts for e-components in the powertrain. AVL will apply the newly developed and advanced WBG semiconductor technology in the area of test-systems for batteries and inverters.

CONTACT

AVL List GmbH

Hans-List-Platz 1

8020 Graz, Austria

Infineon Technologies Austria AG (IFAT)

Headquartered in Villach, Infineon Technologies Austria AG is Infineon’s globally leading competence unit for power semiconductors. The company consolidates expertise in research and development, production, and global responsibility for business performance.

COMPANY DESCRIPTION

Infineon Technologies Austria AG (IFAT) is a 100% subsidiary of the worldwide operating semiconductor producer Infineon Technologies AG and was founded in April 1999. IFAT develops and manufactures semiconductor- and system solutions for all business areas. In Austria, about 1,547 of 3,800 (12/2017) employees are working in the field of Research and Development. Hence, IFAT has the largest R&D unit for microelectronics in Austria. This requires a high level of comprehensive technology know-how in modelling, design and fabrication as well as in the field of security.

In the year 2017 expenses of IFAT in the field of Research & Development were ~428 million Euros, which corresponds to nearly 17% of the business volume of 2,540 million Euros.

In its worldwide 36 research and development locations, 18 manufacturing locations and about 44 sales offices, Infineon designs, develops, manufactures and markets a broad range of semiconductors and system solutions. The focus of its activities is on automotive electronics, industrial electronics, RF applications, mobile devices and hardware-based security.

Combining entrepreneurial success with responsible action, at Infineon we make the world easier, safer and greener. Barely visible, semiconductors have become an indispensable part of our daily lives. Infineon’s components play an essential role wherever electric energy is generated, transmitted and used efficiently. Furthermore, they safeguard data communication, improve safety on roads and reduce automotive emissions.

ROLE & KEY CONTRIBUTION

Infineon Technologies Austria AG is the leader of WP2 “Power Electronic Switches with new Materials (SiC, GaN)” that focusses on new approaches to reduce defect densities and improve the cost performance while doing research work on wide band gap switches and investigating advanced GaN substrates and buffer layers to increase their technology readiness for applications. In its role as project partner and by using the pilot line established in the ECSEL project PowerBase, Infineon Austria aims to contribute to the realization of an industrial grade qualified 100V blocking pGaN HEMT (High Electron Mobility Transistor) e-Mode power-transistor which is not available on the market until now. The company will closely work together with diverse Use Cases.

CONTACT

Infineon Technologies Austria AG

Siemensstraße 2

9500 Villach, Austria

University of La Coruña

University of La Coruña (UDC) is a generalist state university with its main campus in the city of La Coruña and a second campus in the city of Ferrol, accounting in total for about 20,000 students. The School of Naval and Industrial Engineering is located in Ferrol, a naval base of the Spanish Navy and home to major shipyards for war and civil shipbuilding.

COMPANY DESCRIPTION

Laboratory of Mechanical Engineering (UDC-LIM)

The Laboratory of Mechanical Engineering (LIM) is in the above mentioned school and conducts research in the field of multibody system dynamics. The lab was formally founded in 2002, but its coordinator has worked on multibody dynamics since the mid-eighties. The group expertise is in the development of detailed car models and input/state observers for real-time automotive applications, and in co-simulation.

The Laboratory of Mechanical Engineering (LIM) carries out state-of-the-art research in multibody system dynamics, with a strong expertise in

- Efficient multibody algorithms for the simulation of complex mechanical systems, including flexible bodies, contacts, and impact phenomena.

- High-fidelity vehicle models and simulation methods for real-time automotive applications in multi-platform environments.

- Multi-rate co-simulation and interaction of mechanical systems to multiphysics environments with electric, electronics, hydraulics, and thermodynamics components.

- Numerical integration methods, optimization, and control.

- State observers and state estimation in automotive applications and embedded systems.

- Biomechanics of the human motion, including musculo-skeletal modelling and simulation.

Group of Electronic Technology and Communications (UDC-GTEC)

GTEC is the Spanish acronym of the Group of Electronic Technology and Communications (http://www.gtec.udc.es), a research group of the Department of Computer Engineering at the UDC, and also part of the CITIC, focused on wireless communications engineering, including prototyping and experimental evaluation of advanced radio interfaces, experimental wireless channel characterization and modelling, wireless sensor networks for positioning and delivery of contextual information, and vehicular communications.

GTEC has a long-standing expertise in the field of wireless communication engineering. The specific research lines at GTEC are:

- Iterative and adaptive signal processing techniques for estimation, equalization, synchronization and interference cancellation in wireless communications.

- Design of capacity approaching channel coding techniques.

- MIMO (Multiple Input Multiple Output) transmission technologies.

- Data Communications Equipment prototyping with special emphasis on the wireless standards such as IEEE 802.11 (WiFi), IEEE 802.16 (WiMAX) or Long Term Evolution (LTE).

- Wireless Sensor Networks for positioning and delivery of contextual information.

- Wireless communications in vehicular environments, with special emphasis on road and railway transportation.

- Radio Frequency Identification (RFID) technologies.

GTEC has developed a multiuser wireless testbed consisting of fully interoperable heterogeneous frequency-agile and flexible nodes that cooperate among them to address measurements in realistic scenarios, including indoor and outdoor, high-mobility, and multi-terminal. Such measurements can be used to evaluate the performance and/or validate existing wireless communication systems such as LTE or WiMAX.

GTEC also has experience in experimental wireless channel characterization by means of positioned testbed measurements. In contrast to channel sounders, testbeds enable the simultaneous evaluation of the performance of wireless links and the characterization of the underlying wireless channel directly from the communications signals carrying out user data over the air. Once the channel is characterized, it is also possible to derive high-level figures of merit, such as delay or jitter, by means of simulations.

GTEC has also a vast experience in the development of client-server software in general and, more specifically, in the development of mobile apps which interact intensively, and at low level, with smartphone

Finally, GTEC offers remarkable experience in technology transfer to private industry through projects related to the development of critical wireless communication systems and their applications in sectors such as defense or railway and road transportation. It is worth highlighting the successful collaboration between GTEC and Indra in the development of a tactical wireless systems as well as the fruitful collaboration with Navantia in a Joint Research Unit for the development of the Navantia’s Shipyard 4.0 model.

ROLE & KEY CONTRIBUTION

LIM will participate in use-case 4, related to WP1 and, mainly, WP5, developing simulation technologies and methods on system level.

More specifically, our role in the project will be to provide support to Tecnalia and the rest of partners in the development of a real-time model-based environment for the simulation and testing of in-wheel electrified powertrain concepts with dual inverters for different vehicle platforms and configurations. Our key contribution will be the use of computational dynamics to address the real-time co-simulation of detailed mechanical models of the vehicle and discrete thermal and electrical and electronics models of the e-powertrain components. This will enable virtual driving using realistic test scenarios since very early research stages, based on a custom-built vehicle simulator that allows hardware-in-the-loop and software-in-the-loop simulation.

GTEC will participate in use-case 4, related to WP1 and, mainly, WP3, developing the telematics hardware of the “dual inverter” architecture and its experimental evaluation.

CONTACT

University of La Coruña – Laboratory of Mechanical Engineering (UDC-LIM)

Escuela Politecnica Superior, Mendizabal s/n

15403, Ferrol, Spain

University of A Coruña – Group of Electronic Technology and Communications (UDC-GTEC)

Facultad de Informática, Campus de Elviña s/n

15071, A Coruña, Spain

VIRTUAL VEHICLE RESEARCH CENTER

VIRTUAL VEHICLE is a leading international R&D center for the automotive and rail industries. The center focuses on the advanced virtualization of vehicle development.

COMPANY DESCRIPTION

VIRTUAL VEHICLE is a leading international R&D center for the automotive and rail industries, located in Graz, Austria. The center focuses on the advanced virtualization of vehicle development. This linking of numerical simulations and hardware testing leads to a powerful HW-SW system design.

VIRTUAL VEHICLE’s international partner network consists of:

- 80+ international industrial partners (OEMs, Tier 1 & Tier 2 suppliers, software vendors)

- 40+ international scientific institutions

VIRTUAL VEHICLE is the largest COMET funded research center and is also active in 30+ EU-projects. Furthermore, VIRTUAL VEHICLE offers a broad portfolio of contract research for the vehicle development.

FIELDS OF EXPERTISE

- Automated Driving: development, validation, test, operation, and continuous self-diagnosis of fail-operational automated driving architectures and ensuring the coexistence of highly automated vehicles with conventional vehicles on the road.

- Safety & Security

- Efficiency & Comfort

- Digital Operation

- Efficient Development

- Advanced Testing

ROLE & KEY CONTRIBUTION

VIF will bring in its knowledge about automotive domain and its hardware expertise regarding electronic components, targeting next generation GaN- and SiC-based components for future electric vehicles in highly automated/autonomous driving scenarios. VIF will also connect the electronic component and system level by its modular co-simulation environment.

In WP3 – in tight interaction with AVL – VIF will provide a modular simulation environment, allowing the interaction with real hardware components (real-time co-simulation) for architecture optimization. By using this simulation approach, the power-net stability and efficiency will be validated and methods for pre-conditioning and reliability testing can be evaluated. Furthermore, novel GaN- and SiC-based electronic components (e.g. high-frequency inverters) will be simulated and advanced control strategies will be developed in alignment with the use-cases conducted in WP1.

Within WP4, VIF will work on the thermal simulation of GaN- and SiC-based system-on-chip solution on both component and system level. The modular simulation environment deployed in WP3 will form a sound basis to jointly simulate thermal, electromagnetic, and electrical behaviour for different EMC levels, stress and load profiles.

Within WP5, VIF will work on safety requirements and functional system safety analysis on electronic component and system level. Special focus will be put on the nominal performance and the safety of the intended functionality (emerging ISO PAS 21448). Furthermore, VIF intends to implement a HW/SW framework (based on WP3 results) to investigate defect rates, component reliability, and durability.

CONTACT

Virtual Vehicle Research Center

Inffeldgasse 21/A

8010 Graz, Austria

Vrije Universiteit Brussel (VUB)- MOBI

The Mobility and Automotive Technology Research Centre (MOBI) is a multidisciplinary research group at the Vrije Universiteit Brussel (VUB). MOBI is a leader in electromobility and socio-economic evaluations for sustainable mobility and logistics. From a technological perspective, MOBI has a leading position in electromobility, thanks to its experience of over 40 years in electric, hybrid and fuel cell vehicles R&D. The MOBI team consists of close to 100 researchers covering the different research areas. MOBI has a vast experience in the development and characterization of electric power trains and components for vehicles.

COMPANY DESCRIPTION

The Mobility and Automotive Technology Research Centre (MOBI) is a multidisciplinary research group at the Vrije Universiteit Brussel (VUB). MOBI is a leader in electromobility and socio-economic evaluations for sustainable mobility and logistics. MOBI develops electric and hybrid vehicles technologies and evaluates new concepts in mobility and logistics on their sustainability. MOBI aims at a better and safer mobility of people and goods, to reduce congestion and environmental impacts in urban and inter-urban areas, and to improve operational efficiency. Its multidisciplinary team of 100 specialists enables a holistic approach.

MOBI research and main activities:

• Research in electromobility for over 40 years;

• Research and development of energy storage systems for traction and stationary applications in MOBI’s Battery Innovation Centre (BIC);

• Development of advanced power electronics converters with emerging switching technologies (SiC and GaN);

• Assessment, co-design and optimisation of electric and hybrid powertrains;

• Unique range-based LCA methodology for the entire automotive sector;

• Standardization and charging infrastructure for electric vehicles;

• Evaluation of the sustainability of logistics systems and examining ways of reducing externalities in logistics. In-house tools include the Intermodal simulator (LAMBIT) and Transport Agent-BAsed Model (TRABAM);

• In-house socio-economic evaluations methods, such as the decision-making model MAMCA© and the External Cost Calculator;

• Research on different aspects of urban mobility: travel behaviour analysis, mobility management, co-creation, travel time use, equity and stakeholder participation

MOBI has an extended network of international academic, industrial and public authority contacts, and works closely together with different international scientific associations, including AVERE, EGVIA, EPE, EERA, EMIRI, UITP, VIM, ECTRI, ASBE, …

The group possesses considerable expertise in the scientific and operational management of multi-partner research projects and is currently involved in 26 European projects. It has a unique position to address the EU roadmapping activities.

ROLE & KEY CONTRIBUTION

VUB-MOBI is WP 3 leader ‘Architecture optimization and controllers for electronic systems’. In this WP, it will be in charge of the development and design of switching topologies, control algorithms, thermal concepts and strategies for the different defined applications and use-cases. In addition, it will be in involved in other WPs regarding specifications & requirements, thermal management in WP4, simulation and testing of the developed systems in WP5.

VUB-MOBI is the main powertrain expertise centre in Belgium. Thus, its expertise in the field of power electronics and in particular for the next generation WBG will be of high importance. Then, VUB-MOBI will provide the required expertise in the field of modelling (switching topologies, strategies, thermal management, and system simulation) and testing in its state-of-the-art facilities.

CONTACT

Vrije Universiteit Brussel

Pleinlaan 2

1050 Brussels, Belgium

FH JOANNEUM Gesellschaft mbH

FH JOANNEUM, founded in 1995, is one of Austria's leading Universities of Applied Sciences running educational programs at bachelor and master level in the fields of Engineering, Management and Information Technology among others. With more than 530 employees and about 800 external lecturers FH JOANNEUM offers to more than 4000 students a high-level, application-oriented foundation for a successful future career.

COMPANY DESCRIPTION

Teaching expertise of the Institute Electronic Engineering relies on strong Research and Development activities, which are carried out primarily in close cooperation with Austrian industry as well as with European partners, which is done in EU funded projects where FH JOANNEUM takes part.

Special research interests of the Institute of Electronic Engineering are new technologies and architectures for power converters in automotive and renewable energy applications, accompanied by FPGA-based computational platforms facilitating extremely high control dynamics. In this field the Institute of Electronic Engineering has built a solid know-how. This know-how goes from the modelling and simulation of power converters till the development of lab prototypes.

ROLE & KEY CONTRIBUTION

Due to numerous projects and realized prototypes in the field of application of wide-band-gap (WBG) switches, FH JOANNEUM (FHJ) is especially interested in contributing to the work packages WP1, WP3 and WP5 with possible supporting activities in WP4.

Main contributions will be:

Preparation (adaptation) of an FPGA-based rapid prototyping computational platform for implementing advanced control algorithms for ultra-fast switching converter systems for inverters build in UC1.

CONTACT

FH Joanneum

Alte Poststrasse 149

8020 Graz, Austria

IMEC

As a trusted R&D partner of companies, start-ups and academia, research and innovation are in our DNA. We combine our longstanding leadership in microchip technology with indepth expertise in software and ICT to lay the foundation of a more personalized healthcare, smarter cities, cleaner energy and more efficient mobility, logistics and manufacturing solutions. We are a single point of contact for innovators and entrepreneurs who want to explore the potential of advanced technologies.

We are imec. We shape the future.

COMPANY DESCRIPTION

IMEC is a world leading R&D centre for digital technologies with the goal of creating the solutions and building blocks for a better, healthier life in a sustainable environment – through innovations in Nanoelectronics and digital technology. IMEC is headquartered in Leuven, Belgium and has affiliates in the Netherlands, Taiwan, USA, China, India and Japan. We have a staff of over 3500 including almost 700 industrial residents and guest researchers. In 2017, IMEC’s revenue (P&L) totalled more than half a billion euro.

At IMEC scientists and engineers collaborate with experts from top companies, research institutes and universities in semiconductor technologies, imaging, healthcare, energy, communication and the Internet of Things. imec is world-renowned for its expertise in CMOS, imagers, flexible electronics and heterogeneous integration complimented by application-driven research programs including the Intuitive Internet of Things.

IMEC has been pioneering GaN technology for more than 15 years, evolving 200mm wafers to realize GaN-on-Si devices at lower costs while maintaining world-class performance. Our research covers GaN epitaxy as well as device engineering and processing technology.

ROLE & KEY CONTRIBUTION

Imec will be involved in the tasks concerning the development of advanced substrates for improved performance and cost reduction, and in the task for reliability improvement. In particular imec’s involvement is in WP2 where a low-cost sputtering process for 200mm GaN-on-Si wafers will be developed by FEP in collaboration with imec. Apart from this imec will also develop poly-AlN substrates, which enable GaN switches with increased breakdown fields over GaN-on-Si (with a target VBD of 1.2kV). For both approaches, imec will develop epi buffers, process test structures, devices and perform electrical characterization. Concerning the reliability improvement, imec will be involved in the reliability evaluation of the switches processed within HiPERFORM.

CONTACT

IMEC

Kapeldreef 75

3001 Leuven - Belgium

AVL Software and Functions

AVL is the world's largest privately owned company for development of powertrains (combustion engines, hybrid systems, and electric drive) as well as simulation and test systems for passenger cars, trucks and marine engines.

AVL Software and Functions in Regensburg (AVL SFR) was founded 2008 as 100% daughter of AVL Graz, The AVL group the worldwide competence Center for software and electronics. Mainly high experienced engineers for automotive software, function and electronic development are with AVL SFR (~320 employees). AVL SFR is fully embedded in the AVL network for all disciplines and areas.

COMPANY DESCRIPTION

For E-Mobility:

For electric mobility, AVL develops highly innovative components, systems and detailed solutions covering both hardware and software. Examples include high and low voltage electronic components such as inverters, DCDC converters, controllers and battery management systems but also e-motors and fully integrated systems such as e-axles. Services include requirement engineering, development of prototypes, support for industrialization and series production projects. AVL SFR has developed own development processes and methods according to automotive standards and is equipped with relevant tool chains and test hardware to effectively develop and validate these products. Available test equipment includes various model/software/hardware in the loop test systems and a Power-HIL as well as fully equipped e-motor or powertrain test rigs.

For model based development Combustion, Exhaust, Safety …

One main approach is the model-based development process with the appropriate tool chain for an efficient development for the different applications and related innovations. Furthermore, AVL Software and Functions develops safety-monitoring concepts (including architectural aspects) for new vehicle platforms and have its competences in the enhancement of interface between vehicle-energy management function and grid via wireless communication.

In General:

In the automotive industry, AVL SFR is a well-known and accepted partner for a lot of OEMs and Tier1s worldwide, involved in projects from concept up to serial development.

ROLE & KEY CONTRIBUTION

AVL SFR will take over the lead of WP5 and coordinate the activities on system level design of complex inverters, chargers and test system.

AVL SFR will collaborate with Toyota, IFAG and other partners on the design of a new WBG based inverter system that is able to fulfil the set out efficiency and performance objectives.

CONTACT

Im Gewerbepark B 29

93059 Regensburg, Germany

Infineon Technologies AG

Infineon Technologies AG, Neubiberg, Germany, offers semiconductor and system solutions addressing three central challenges to modern society: Energy efficiency, mobility and security. In the 2016 fiscal year (ending September 30), the company reported sales of Euro 6.4 billion with close to 36,300 employees worldwide.

COMPANY DESCRIPTION

Infineon has long years of experience in semiconductor solutions for automotive and industrial applications and develops, manufactures and markets innovative semiconductor products and complete SoC solutions. Infineon is market leader in automotive semiconductors (sensors, power semiconductors and microcontrollers) in Europe and on place #2 worldwide. The main involved division of Infineon within HiPERFORM is the Automotive Division, in cooperation with the Industrial Power Control Division and the corresponding front end and back end technology providers from the operational organization in Warstein and Regensburg. Further information is available at www.infineon.com.

ROLE & KEY CONTRIBUTION

The contribution of Infineon Technologies is an integrated part of HiPERFORM and covers topic from the locations in Munich, Warstein and Regensburg.

CONTACT

Infineon Technologies AG

Am Campeon 1-12

85579 Neubiberg, Germany

Slovak University of Technology in Bratislava / Institute of Electronics and Photonics

The Institute of Electronics and Photonics of the Slovak University of Technology in Bratislava is active in microelectronics, nanotechnology, IC and Smart system design and test, wireless communication, optoelectronics, sensors, power electronics, and organic electronics.

COMPANY DESCRIPTION

Slovak University of Technology in Bratislava (STUBA) is attended by almost 18000 students and belongs to the leading universities in microelectronics education and R&D activities in the New Member States of EU. STU strives to be an internationally recognized, research-oriented technical university. It seeks to provide a high quality internationally comparable education in the promising (key technologies) fields, based on independent and critical thinking, entrepreneurship and creativity, with a view to practical application and success in life. The university aims to contribute to the economic and social development of the region.

In 2012 STU received the ECTS Label – the most prestigious European certificate awarded in the sphere of tertiary education.

The Institute of Electronics and Photonics of STUBA is active in a field of microelectronics, photonics and sensorics. Its membership in EUROPRACTICE provides access to advanced TCAD modelling and simulation as well as IC design tools. Structure and device characterization and failure analysis either by electrical or analytical and microscopical tools is another strong field of institute activities.

ROLE & KEY CONTRIBUTION

STUBA will take part in characterization and analysis of new substrate materials and heterogeneous GaN buffer structures by advanced electrical, analytical and optical methods. Will study breakdown mechanisms in GaN devices, also with the aid of electroluminescence. It will contribute to the study of failure mechanisms of GaN power devices. 2D and 3D electro-thermal simulation of complex structures and experimental analysis of devices to be tested will be another contribution. Further STUBA will prepare and realize a dissemination plan for effective dissemination of obtained results within the consortia, wide scientific community and public society.

CONTACT

STU

Vazovova 5,

81243 Bratislava, Slovakia

Ideas & Motion S.r.l.

Ideas & Motion S.r.l. (I&M), Cherasco (CN) nearby Turin – Italy, offers high-tech solutions in the field of automotive applications. I&M has a well-recognized position of excellence on some key areas, stemming from more than 100 years of combined experience on innovative projects and related automotive products.

Its biggest technological background is in the design of silicon integrated circuits for the control of electro-actuators, and its integration in automotive powertrain applications.

COMPANY DESCRIPTION

I&M’s core business is to provide engineering services (both HW and SW) to OEM and Tier1 companies in the automotive industry, while also being active as a supplier of Electronic Control Units in niche applications with low volumes and high technological contents.

The company focuses its efforts on some very clear goals:

- priority on R&D, with particular respect to the protection and exploitation of IP

- innovation transfer into products with a high technological content and limited production lots

- "fabless" organization featuring the unique access to technologies and test facilities to support the development of advanced automotive systems through its local industrial partner (e.g. MTM S.r.l.)

Main priority on 3 application areas, as a solid basis for the subsequent expansion on other domains:

- design of integrated circuits and IPs on silicon (e.g. ASIC, ASSP)

- design, development and manufacture of automotive control systems (high-tech for niche applications)

architecture exploration, design, development and manufacture of innovative control systems in the field of electro-mobility

ROLE & KEY CONTRIBUTION

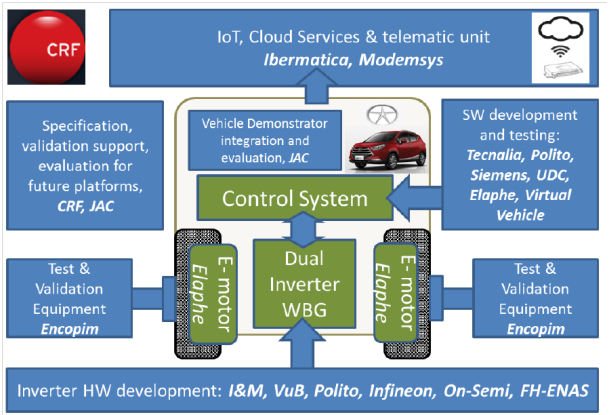

I&M will be involved in the HW/SW design, development and realisation of the dual inverter. In order to do so I&M will be active part of the analysis of the requirements and will provide support for the integration of the dual inverter into the proposed vehicle demonstrator (e.g. JAC compact SUV IEV6S). The physical realization of the dual inverter will be accomplished in the modern assembly line available at I&M; it will cover also the testing, in the lab, and validation on the automotive demonstrator (ref. Use-Case 4).

CONTACT

VIA SANTA MARGHERITA 8

12051 Alba, Italy

Politecnico di Torino

With more than 150 years of history, Politecnico is internationally ranked among the most important universities in Europe for engineering and architecture studies, hosting a 35.000 student community, where 15% is composed of international students [coming from over 100 different countries]. As hub of excellence in the field of education, research and technology transfer in Engineering, Architecture, Design and Urban Planning, it works in close cooperation with the socio-economic system

COMPANY DESCRIPTION

Politecnico di Torino was founded in 1906 and has its roots in the Technical School for Engineers created in 1859.

It is internationally ranked among the most important universities in Europe for engineering and architecture studies, with 33,000 students (out of which 15% are international students coming from over 100 different countries).

Politecnico is a center of excellence for education and research in engineering, architecture, design and planning and it works in close cooperation with the socio-economic system. It is a comprehensive Research University where education and research complement each other and create synergies in order to address the needs of the economic system, of the local community and, above all, of its students.

Politecnico is committed to a strong internationalization process of its teaching, research and technology transfer activities: not only does it work in cooperation with the best universities and research centers in world, but it has also been signing agreements and contracts with important international corporations, as well as local businesses, meaning to be for the latter a focal point for innovation.

ROLE & KEY CONTRIBUTION

Politecnico di Torino is involved in

WP1 (Specifications/Requirements definition for UC4, in detail for the dual inverter dedicated to the in wheel motors)

WP3 (Definition of switching topologies exploiting innovative wide bandgap technology and development of control strategies e-axles with in-wheel motors)

WP5 (Electric vehicle dynamic system simulations, Design and integration of dual inverter prototype, development of safety critical software for dual inverter modules)

Use Case 4 (Support the test activity of the electrified in wheel powertrain)

Researcher being active in the PIEC and CARS Interdepartmental Centers will focus their effort in an interdisciplinary research work dedicated to the development and testing of a dual inverter for in wheel automotive powertrain. The key contribution is due to the implementation of new wide bandgap switching technologies, development and testing of control algorithms for in wheel motors and safety critical software.

The complementary contribution with respect to the industrial partners and other involved research entities is and added value for PoliTo Researcher.

CONTACT

Politecnico di Torino

Corso Duca degli Abruzzi, 24

10129 Torino, ITALY

Heliox B.V.

Heliox is dedicated to transforming inspiring ideas into innovative and reliable high-power products and services. Company’s core business is creating fast charging solutions in the automotive sector, which leads from the basis of intensive R&D and close collaboration with commercial partners.

Heliox’s mission: Creating a sustainable world for the next generations.

COMPANY DESCRIPTION

Heliox, with over 30 years of Professional Power Conversion experience, focuses on creating high quality charging solutions in the most demanding markets. Thanks to its excellent R&D capabilities, Heliox is the right partner of choice to develop your customized power solutions. We enable our customers flexibility and future-proof products with an optimal TCO. From specification phase to design qualification and production, Heliox works in close cooperation with our customers to realize the optimal product. You benefit from best possible energy costs and most efficient grid connection, with Industry’s Highest Charging Efficiency (97%) and Heliox ZERO Reactive Current Technology.

Keep your electric bus fleet sustainable with Heliox.

ROLE & KEY CONTRIBUTION

Heliox will contribute to the HiPERFORM project by identifying the requirement specifications, assessment of the utilization of WBG power devices, demonstrator realization, testing and evaluating of a WBG based power train off-board high power EV charger.

CONTACT

Heliox B.V.

De Waal 24

5684PH, Best, The Netherlands

Elaphe Propulsion Technologies Ltd

Elaphe Propulsion Technologies Ltd was established in 2006 with the focus on the development of in-wheel motor propulsion systems for electric and hybrid vehicles. Today Elaphe is among the most experienced companies in this field – the company boasts more than 12 years of research, development and sales experience in the field of electric vehicles with propulsion power up to 440 kW, over 20 different electric vehicles with their propulsion system installed.

COMPANY DESCRIPTION

Elaphe is focused on in-wheel electric propulsion systems and its core products are three types fo in-wheel motor (S400, M700 and L1500) with suitable inverters and Propulsion Control Unit system solution. Together with partners Elaphe can deliver complete solution including friction brake and all other mechanical and electrical parts of the propulsion system.

The headquaters of Elaphe are in Ljubljana, Slovenia, EU where also the production for Western part of the World is located. In Hangzhou, China, Elaphe has additional manufacturing site for the local market. Elaphe is focused both on further developmnt as well as on manufacturing. The three pillars of the company are Management, R&D and Production.

Elaphe is working with several major global OEMs, currently is running a small scale production and is targeting mass prouction in 2019 and 2020. The products are suitable for advanced two-wheelers and L-category vehicles as well as some of the commercial vehicles and public transportation. Passenger car segment is the main focus of Elaphe.

Elaphe’s main commitment is to bring new environmentally friendly technologies to the vast automotive market. Its innovative potential has been proven in the past by eight great patents and completed projects, where products provided up to 20% higher specific torque compared to competitive solutions.

ROLE & KEY CONTRIBUTION

Elaphe Propulsion Technologies Ltd. is a fast growing SME focused on in-wheel motors and powertrains. Its role in exploitation is the possible introduction of advanced inverters using wide bandwidth semiconductor and enabling high switching frequencies. This is especially useful for compact high pole pair electric machine control, such as in-wheel motors. One of the key tasks will be related to the development of motor control algorithms and software especially focused for inverters operating at high switching frequencies.

CONTACT

Elaphe Propulsion Technologies Ltd

Teslova 30

1000 Ljubljana, Slovenia

JAC-ITALY Design Center S.r.l.

JAC-Italy Design Center is an Italian high-tech competence centre founded in 2005, focus on style, design, engineering and automotive technology research with particular respect to breakthrough solution in the field of Electric cars. It has been established by Anhui Jianghuai Automobile CO., Ltd, which is one of the top EV OEMs in China.

COMPANY DESCRIPTION

JAC-ITALY Design Center S.r.l. is an Italian high-tech competence centre, which is strongly based on the long-lasting tradition and culture available in the automotive domain in Turin. It is focused on style, design, engineering and automotive technology research with particular respect to breakthrough solution in the field of Electric cars. It has been established by JAC Auto (ref. Anhui Jianghuai Automobile CO., Ltd) which is one of the top 3 producers of EVs in China, and in the top 10 in the world. In addition, China is the world’s top investor in EV research and production, and in the future will be the most important center of EV development.

JAC has a strong background in EV, with 6 vehicles in production and with 1 hundred million km covered by 6 generations of JAC Electric Vehicles Compared with other Chinese car companies JAC knows how to contain and optimize costs in design and production in order to achieve a good balance between cost and performance.

ROLE & KEY CONTRIBUTION:

JAC-ITALY Design Center will provide to the project a brand new JAC Motor compact SUV.

A virtual design by CAD model will be accomplished in cooperation with the industrial partners. Then the mechanical engineering activity will take place in order to integrate the e-powertrain in the vehicle.

CONTACT

JAC-ITALY Design Center S.r.l.

Via Torino, 21/b

10044, Pianezza (TO), Italy

Centro Richerche Fiat SCPA

CRF (Centro Ricerche Fiat), headquartered in Orbassano (Turin) with other branch sites in Italy, was established in 1978.

COMPANY DESCRIPTION

As a focal point for research activities of FCA (Fiat Chrysler Automobiles), CRF has the mission to:

- develop and transfer innovative powertrains, vehicle systems and features, materials, processes and methodologies together with innovation expertise in order to improve the competitiveness of FCA products;

- represent FCA in European collaborative research programs, joining pre-competitive projects and promoting networking actions;

- support FCA in the protection and enhancement of intellectual property.

Also through the cooperation with a pan-European and increasingly global network from industry and academia, CRF conducts collaborative research initiatives at the national and international levels in partnership with all the key public and private stakeholders concerned with sustainable mobility, targeting specifically the industrial exploitation of research.

CRF develops research and innovation along the three principal axes of sustainability: Environmental Sustainability, Social Sustainability and Economically sustainable competitiveness.

ROLE & KEY CONTRIBUTION

CRF has a well-known and recognised expertise in R&I activities in the field of electrified propulsion system and vehicles and will lead WP1 (Use-cases and e-component specs definition) and give support to integration and validation and e-devices evaluation.

CONTACT

Strada Torino 50

10043 Orbassano, Italy

Fraunhofer Institute for Electronic Nano Systems - ENAS

Fraunhofer ENAS focuses on applied R&D for smart systems integration technologies, including design, component fabrication, system integration, encapsulation as well as on material, reliability, and on functional safety.

COMPANY DESCRIPTION

The Fraunhofer Research Institute for Electronic Nano Systems ENAS in Chemnitz focuses on research and development in the fields of smart system integration by using micro and nanotechnologies with partners in Germany, Europe and worldwide. It has strong experience in the design and the simulation of wired and wireless communication systems in harsh environments for a wide field of applications. Fraunhofer ENAS is a specialist of early stage feasibility studies and pre‐design methodologies for customers in Automotive and Aeronautics.

With its Micro Materials Center (MMC), Fraunhofer ENAS also does world‐leading research on thermo‐mechanical reliability of micro and nano components in smart systems. It operates a full scale lab for stress testing, analysis, and numerical simulation assessing and optimizing the thermo-electro-mechanical reliability and functional safety of smart power & ICT electronics systems for automotive and other fields of application with harsh environmental conditions.

ROLE & KEY CONTRIBUTION

Fraunhofer ENAS contributes to WP4 by multi-load testing and experimentally assisted physics of failure simulation and determination (PoF), interacting with the project partners AVL, OnSemi, Heliox, Elaphe, I&M, which provide the information as well as the components and systems samples therefore. Additional to that Fraunhofer ENAS contributes to WP5 by key failure identification for future maintenance & repair technologies.

CONTACT

Fraunhofer ENAS

Technologie-Campus 3

09126, Chemnitz, Germany

Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP

The Fraunhofer FEP is located in Dresden and focuses on developing innovative solutions, technologies and processes for surface modification and organic electronics. Our aim is to seize the innovation potential of organic electronics, electron beam and plasma technology for new production processes and devices and to make it available for our customers. We support our partners from industrial and public sectors with customized services to transfer research into applications.

COMPANY DESCRIPTION

The Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP works on innovative solutions in the fields of vacuum coating, surface treatment as well as organic semiconductors. The core competences electron beam technology, sputtering and plasma-activated deposition, high-rate PECVD as well as technologies for the organic electronics and IC/system design provide a basis for these activities.

Thus, Fraunhofer FEP offers a wide range of possibilities for research, development and pilot production, especially for the processing, sterilization, structuring and refining of surfaces as well as OLED microdisplays, organic and inorganic sensors, optical filters and flexible OLED lighting.

Feasibility studies, to evaluate surface coating or the integration of organic electronics in devices and pilot production, to facilitate the introduction of new customer products to the market, are also included in our range of services. The upscaling of technologies to industrial quantities and the integration into suitable plant technology and into existing production processes as well as the possibility of technology transfer and licensing are essential services of our institute. The cost efficiency of a technology for industrial production is always taken into account.

ROLE & KEY CONTRIBUTION:

Within Work Package 2 (Power electronic switches with new materials), FhG-FEP will develop a novel magnetron pulse reactive sputtering process and source device for the high-purity and high precision epitaxial AlN and GaN layer deposition on silicon substrates. Compared to the known conventional MOCVD processes this technology will be a potential low-temperature process at essential higher deposition rates (~ 100nm/min) and therefore higher throughput with substantial lower cost. Wafer bow, uniformity and scalability for large wafers shall be significantly improved. This development will be done together with the partners within the project as a unity of epitaxial deposition technology development (FEP), together with the deposition tool development (scia, Creavac), the sputter source development (FEP) and sputter target technology development (Sindlhauser).

CONTACT

Fraunhofer FEP

Winterbergstr. 28

01277 Dresden, Germany

ON Semiconductor Belgium BVBA

ON Semiconductor (Nasdaq: ON) is driving energy efficient innovations, empowering customers to reduce global energy use. The company is a leading supplier of semiconductor-based solutions, offering a comprehensive portfolio of energy efficient power and signal management, logic, standard and custom devices. The company's products help engineers solve their unique design challenges in automotive, communications, computing, consumer, industrial, medical and military/aerospace applications. ON Semiconductor operates a responsive, reliable, world-class supply chain and quality program, and a network of manufacturing facilities, sales offices and design centers in key markets throughout North America, Europe, and the Asia Pacific regions.

COMPANY DESCRIPTION

ON Semiconductor Belgium BVBA is a strategic development and production center within the global corporation with a focus on providing solutions and products for automotive, industrial and consumer applications. The Belgian site comprises almost 7% of the global ON Semiconductor revenue. 80% of the ON Semiconductor Belgium revenue is generated through products and solutions for automotive applications, while the remaining 20% is through industrial and consumer applications related products. In order to meet the constant demand for more advanced, energy-efficient and cost-competitive technologies, ON Semiconductor Belgium is required to continuously innovate. For this, ON Semiconductor Belgium has an extensive R&D group as part of the worldwide corporate R&D department and which is one part of a set of multidisciplinary centers of excellence. The main focus of the R&D team is the development of novel device concepts, advanced and robust process technologies, high voltage and high power processes. Within the R&D team a specific focus is on the research and development of power devices on GaN-on-Si, advanced Si-based smart discrete power semiconductors such as trench-based superjunction devices, and advances Si-based power integrated circuits. The team also has a long history in the reliability and automotive qualification of Si discrete and integrated power device technologies.

ROLE & KEY CONTRIBUTION

- Development of e-mode p-GaN devices in the range of 650V. This work includes the development of package properties (parasitics / thermal), investigation of the stability of the pGaN HEMT under HTRB and HTGB, quality and defectivity of the pGaN Gate module, electro migration capability of the backend of line process, comparative analysis between different methods to quantify dynamic Ron, research into a methodology to link dynamic Ron effects between test and final application, short-circuit and unclamped-inductive-switching tests in packaged pGaN devices.

- Development of a Virtual Prototyping methodology, including the study of switching- and losses with the actual multi-physics TCAD device as the center of the simulations. Special focus will be on switching speeds and waveforms, and the use in different topologies. Spice models will be available to look at the overall behavior of the devices (form factors, EMC effects), and use in thermal simulations. In this way parallelization issues can be studied.

CONTACT

ON Semiconductor Belgium BVBA

Westerring 15

9700 Oudenaarde, Belgium

NEDERLANDSE ORGANISATIE VOOR TOEGEPAST NATUURWETENSCHAPPELIJK ONDERZOEK

TNO (Nederlandse Organisatie voor toegepast-natuurwetenschappelijk Onderzoek TNO) is one of the major contract research organisations in Europe. With a staff of approximately 3500 and an annual turnover of 580 million Euros, TNO is carrying out research in order to achieve impact on the following seven themes: Healthy Living, Industrial Innovation, Transport and Mobility, Energy, Built Environment, Information Society, and Defence, Safety and Security. TNO functions as an intermediary between basic research organisations and industry. By translating scientific knowledge into practical applications, TNO contributes to the innovation capacity of businesses and government. TNO is involved in many international projects (about 30% of the market turnover), including EU-funded collaborations.

COMPANY DESCRIPTION

In the theme of Transport and Mobility applied research is carried out for the automotive industry and related branches. The expertise covers relevant technological aspects as well as the influence of human behavior. The focus is on innovation in the areas of reliable transport systems and safe and clean mobility.

In the research group of Powertrains, the main activities are testing, modelling and control development for many types of powertrains and after treatment systems. Strong relations exist with university research groups that are active in the same domains. The laboratories of Powertrains are situated on the High Tech Automotive Campus Helmond. The research group of Monitoring and Control Services brings IT solutions for complex monitoring and control challenges in domains such as Sustainable Energy, Smart Industry, Defence and Smart Cities.

ROLE & KEY CONTRIBUTION

In HiPERFORM, TNO will focus on the validation methodologies by developing a unique capability for full cycle and charging assessment of electrified vehicles. This project contributes to a growth area in TNO’s, technology proposition by the development of tools required for assessment of vehicles in realistic scenarios. An important tool to achieve this goal is the development of semi-virtual testing environments. With the charger-in-the-loop automated test framework being developed within HiPERFORM, various assessments such as the role of climate on the performance of high temperature power electronics, the charge acceptance of battery systems at extreme temperatures, as well as preconditioning techniques for the vehicle or its components can be assessed. The aforementioned assessments will give valuable insights into the real-world challenges faced by the electrified transport industry in Europe, and enable TNO to provide consultancy towards transport operators, authorities and OEMs on possible solutions.

Within UC6 the scope of work, (as show in the figure below) a complete charger-in-the-loop setup composing of: high-level charging strategies (developed by Powerdale), (super) fast charger up to 300kW (developed by Heliox) and battery emulator (developed by TNO) will perform the analysis under various working conditions similar to what the future chargers are dealing with in the real life environment, including harness test with the variations of climate (humidity, pressure, temperature). The results of these tests are the preliminary feedback to the electric vehicle charger manufacturers (like Heliox and similar parties) will take into account for their product improvement before the reaching the market.

CONTACT

NEDERLANDSE ORGANISATIE VOOR TOEGEPAST NATUURWETENSCHAPPELIJK ONDERZOEK

Anna van Buerenplein 1

2595 DA, The Hague, the Netherlands

Siemens Industry Software NV

Siemens Industry Software (SISW) is an engineering innovation partner for companies in the automotive, aerospace, and other advanced manufacturing industries. With a unique combination of 1D and 3D simulation software, testing systems, and engineering services, SISW focuses on areas from system dynamics, structural integrity, and sound quality to durability, safety, and power consumption.

COMPANY DESCRIPTION

Siemens Industry Software NV (SISW) is a Belgian company, constituting part of the Simulation and Test Solutions (STS) business segment within Siemens PLM Software. SISW originated as LMS International, a spin-off company from the KU Leuven, developing into a world-leading position for advanced engineering solutions for the mechanical and mechatronic industry. In 2013, LMS was acquired by Siemens to complement its offering on design engineering software within the „Digital Factory” division. More specifically, SISW develops and markets testing systems, multi-domain simulation software and engineering services to support product design in relation to critical performance parameters such as safety, fuel economy, noise and vibration, structural integrity, and life time. SISW employs about 400 people in Belgium, of which a significant fraction works in R&D. While its main markets are the automotive and aerospace ones, its solutions are adopted in all sectors where mission critical performance must be ensured. SISW continuously innovates its solutions through substantial investments in R&D. This innovation process is performed in close collaboration with both major end users, reflecting the actual market needs and with leading universities and research centres, to contribute with breakthrough technologies. As part of this strategy, SISW has a policy of hosting visiting students, researchers and experts, many of which pursue mixed industry-academic doctoral degrees.

ROLE & KEY CONTRIBUTION

Siemens Industry Software will focus on innovative methodologies for the preliminary design of power electronic components and systems. It will consider aspects like architecture generation, formal specification, and formal verification for automating the initial phases of the design process. SISW will consider performance and safety attributes for distinguishing between the created component/system architectures.

CONTACT

Siemens Industry Software NV

Interleuvenlaan 68

3001 Leuven, Belgium

Powerdale NV

POWERDALE is pursuing the development of innovative solutions (Hard- and Software) around energy management and electric mobility, including billing processes, integrating local solar generation into the charging process and intelligent management of the charging process.

We manufacture a series of charging stations and smart cables to load electric vehicles. Next to this, we have developed a software platform to support a whole set of business processes from driver, to mobility manager and fleet companies.

We have a similar approach for energy management, where we can collect via different channels consumption data from sensors and meters and present them on a Taylor made web interface. Both businesses are integrated in order to offer smart charging solutions for mini and micro grids.

COMPANY DESCRIPTION

The company, established in 2003, has grown over the years from an innovation partner to an important actor in the field of Energy Management and Electro Mobility.

Innovation is in the DNA of the company. An experienced team of hardware and software developers accompanied by business experts have put together a market offering to is an answer to the challenges of the electrification of mobility. Smart charging processes allow to load electric vehicles taking into account the expectations of the drivers and the capability of the site and/or the grid.

Energy management solutions cover Energy Management Systems in general as well as specific functions for Closed Distribution Systems.

ROLE & KEY CONTRIBUTION

The role of Powerdale within this project is to develop the methodologies needed to support the design, verification and validation of both on-board and off-board charging stations based on GaN and SiC technology respectively.

Key Contribution:

- Development of a high-level charging management system and communication interfaces that are needed for high-power off-board DC charger.

- Design and manufacturing a low power on-board charger based on GaN technology.

- Integration, verification, validation, Test, and evaluation the optimized design of EV charger.

CONTACT

Powerdale

Rue des Pères Blancs, 4

1040 Brussels Belgium

scia Systems GmbH

scia Systems is a German full range supplier of advanced ion beam and plasma processing equipment. The systems are applicable for several coating, etching and cleaning processes in the production of microelectronics, MEMS and precision optical components. Scia Systems stands for highly reliable equipment, comprehensive service and superior technology support.

COMPANY DESCRIPTION

Scia Systems is a German full range supplier of advanced ion beam and plasma processing equipment. The systems are applicable for several coating, etching and cleaning processes in the production of microelectronics, MEMS and precision optical components, in both, high volume production as well as research and development environments.

Due to their flexible and modular design, the systems can be configured according to customer specific requirements. Amongst others by combining several vacuum process chambers into cluster or in-line solutions. Together with our worldwide service partners, we offer comprehensive service and superior technology support.

TECHNOLOGY PORTFOLIO

- Ion Beam Trimming (IBT)

- Ion Beam Etching and Milling (IBE/IBM)

- Dual Ion Beam Sputter Deposition (DIBD)

- Plasma Enhanced Chemical Vapor Deposition (PECVD)

- Reactive Ion Etching (RIE)

- Magnetron Sputtering

- Plasma Cleaning

ROLE & KEY CONTRIBUTION

The manufacturing of high-power electrical switches based on industry-standard silicon wafers require the development of process hardware, which has high performance and high durability. As an experienced processing system manufacturer, scia Systems GmbH designs, manufacturers and integrates the required components, which allow the wafer pre-clean and the deposition of epitaxial Aluminum-nitride at Fraunhofer FEP. The key contribution is the development of a substrate holder which can heat up a wafer to a temperature of 1000 °C for more than one hour, which is one step beyond the current rapid-thermal processing used in semiconductor industry. Additionally, hydrogen plasma pre-clan is integrated, which provides an ultra-pure wafer surface necessary for the epitaxial layer growth.

CONTACT

scia Systems GmbH

Annaberger Str. 240

09125 Chemnitz, Germany

Fundación Tecnalia Research & Innovation

TECNALIA is a benchmark research and technological development center in Europe. We offer a different business perspective: because we create solutions in co-operation with companies to provide value through technology.

COMPANY DESCRIPTION

TECNALIA is the first leading private and independent research and technology organization in Spain and the 5th largest in Europe, employing more than 1.300 expert and international people (164 PhDs) and income of 131M€ and over 4.000 clients. Tecnalia operates in the following market sectors: Industry and Transport, ICT, Sustainable Construction, Energy and Environment, Innovation Systems, and Health and Quality of Life, and it is very active in FP7, participating up to December-2013 in 377 projects and coordinating 81 of them.; And, and participating in H2020 in 131 projects and coordinating 29 of them. TECNALIA is also participating within the launching of the main KIC’s of the EIT, the KETs, the FET Flagships initiatives, towards the Horizon 2020 Programme, where TECNALIA is actively involved, as well as in the definition of other EU Work Programmes, through CDTI, EC, etc. TECNALIA has also key alliances with the main EU research centres through the EUROTECH, EARTO, JIIP, and ERANET AERTO. TECNALIA belongs to the previous Artemis Steering Board, and now ECSEL Board, and belongs to ENISA NIS Groups of Experts on Security, PPP-Green Vehicles (EGVI), PPP-Big Data, EARPA, ERTICO, SEF - Stakeholder Engagement Forum on Micro & Nanoelectronics.

TECNALIA is further involved in several recently ECSEL projects like ENABLES3, 3CCAR, AUTODRIVE (AUTOMOTIVE ECSEL Lighthouse initiative), IoSENSE, SCOTT, SECREDAS, PRYSTINE, HI-PERFORM, i-DEV-4.0. TECNALIA has been granted with FP7 and H2020 Projects like MOBINET, VRA, SARTRE, CITYMOBIL2, UNCOVERCPS, ECOCHAMPS, EUNICE, SYRNEMO, SAFECITY, SAFEADAPT, STEVE, SERIOT, EUNICE, CARTRE, NATURE4CITIES, ADVICE, ECOCHARMS, RAGTIME, HIFI-COMPONENTS, etc, in the AUTOMOTIVE Sector

ROLE & KEY CONTRIBUTION

WP1 - Use Case specification, demonstration & evaluation: Tecnalia will support the use case & requirements specification from control system, including virtual driving test cases for CRF/JAC in-wheel in motor use case, till the integration of functional software into the inverter ECU (I&M).

WP3 – Architecture optimization and controllers for electronic systems: Tecnalia will develop functional software using model based design which will be embedded into the inverter ECU (I&M). Tecnalia will support CRF for NVH validation using advance instrumentation and IoT cloud platform to study field data, also supporting the reliability integration.

WP4 - Packaging & materials on component-, module-, and inverter level, thermal management: Tecnalia will develop and integrate on inverter control unit of specific cooling management algorithms based on thermal image of e-motor and power inverter, adapted for final cooling concept.

WP5 – System developing with respect safety and Reliability Testing & Simulation methodologies & technologies: Tecnalia will develop a virtual framework using their in-house simulator including vehicle platform ECU virtualization, and real world scenarios allowing virtual driving validation. Tecnalia will participate with Spain-consortia in development of a telematics control unit and cloud services to monitor the performance of the inverter using predictive maintenance strategies together with FHG-ENAS.

CONTACT

Fundación Tecnalia Research & Innovation

Parque Científico y Tecnológico de Gipuzkoa, Mikeletegi Pasealekua 2

20009 Donostia - San Sebastian, Spain

CREAVAC GmbH

CREAVAC has focused on coating of plastic parts. In addition to job coatings CREAVAC features new vacuum coating technologies including equipment design, construction as well as research and development.

COMPANY DESCRIPTION

CREAVAC is uniting the developement and manufacturing of coatings in high vacuum with the construction of vacuum plants for serial coatings of materials such as plastics, glas, wafer, flexible metal and other flexible substrates.

In the area of coating equipment, CREAVAC focuses mainly on technologically oriented specialized solutions. We offer Vacuum- equipment for production and laboratory use with different coating sources like thermal evaporation, E- beam and sputter techniques, PLD or Plasma technologies.

In addition, CREAVAC provides further technologies, such as laser engraving and Tampon printing.

ROLE & KEY CONTRIBUTION

The CREAVAC contributions to WP2 are focused on the coating equipment development for the GaN deposition process.

CONTACT

CREAVAC-Creative Vakuumbeschichtung GmbH

Sporbitzer Ring 9

01259 Dresden, Germany

Eindhoven University of Technology

Public university for higher education with main objective to develop knowledge and technology and to educate researchers.

COMPANY DESCRIPTION

The section “Electromechanics and Power Electronics” (EPE) is part of the Department of Electrical Engineering of TU Eindhoven (TU/e), with as mission to conduct fundamental research in the broad area of Electromechanics and Power Electronics, with emphasis on modelling, analysis, design trajectories and multi-objective optimization of energy conversion systems. Power Electronics related research is mainly focused on multi-port converter systems with added functionality and improved power quality for high-precision applications and also for the interface, power management, and grid connection of decentralized energy generation and storage. A steady increase over the last decades in the power rating of semiconductors has opened the door for using more power electronics in power systems. New opportunities rise for the application of power electronics in transmission and distribution systems, including DC/AC conversion. Since power electronics is an expensive technology we try to influence and control the power flow with small converters. We strive to use the control possibilities that existing converters have to improve the power quality of the systems.

ROLE & KEY CONTRIBUTION

An increase in load from EV’s puts additional demand on existing grid infrastructure. To avoid huge investments into the grid, practical and timely solutions are of great value. In this context, smart bi-directional chargers are the key to enable flexible interfaces between EV’s and the local grid. With the fast increasing amount of local energy generation and storage, these converters will also take over the key responsibility of maintaining stability and quality of the grid from central power plants. In high-power applications, the lower switching frequency due to the limitation in switching performance of high-voltage Si-based semiconductors only allows for the selection of a few voltage or current harmonic components to be processed by active filtering techniques through power electronic converters. However, besides the primary benefits of wide band-gap semiconductor technology on system component level, such as reduced volume and higher efficiency, the higher switching frequencies as attainable by SiC devices allows the advancement of existing active filtering methods in order to improve the control accuracy and the dynamic behavior of electronic power converters, improving therefore the quality of the processed energy. Hence, our ambition is to integrate extra control features in bidirectional EV chargers aiming at optimizing grid energy throughput and, at the same time, enhancing the grid voltage quality at the point of connection of the converters. Modelling and analysis and implementation of enhanced converter control concepts will be put forward by TU/e.

CONTACT

Eindhoven University of Technology

De Zaale, 19

5600 MB, Eindhoven, The Netherlands

Sindlhauser Materials GmbH

Sindlhauser Materials GmbH was founded in 1995, has 25 employees, a turnover of around 7.2 Mio EUR and the main products are ceramic cathodes and sputter targets.

COMPANY DESCRIPTION

Sindlhauser Materials is focused on the production of ceramic cathodes (Lanthanumhexaborides), sputter targets (ceramics, metals alloys) and bonding of targets on Cu-backing plates. We are running several high temperature sintering furnaces, up to 2300°C, casting equipment for high purity non-ferrous metals, bond shop for target soldering, glove boxes for handling high pure metal powders and cleaning equipment for precision optic application. We supply cathodes and targets worldwide and are qualified supplier to the optical industry, automotive- and tool coating industry, sensor manufacturers as well as research institutes, like Fraunhofer, and universities.

ROLE & KEY CONTRIBUTION

The contribution of Sindlhauser Materials GmbH is focused on the development of a handling- and controlled casting technology for ultra-pure low melting Ga targets and the bonding on a Cu-backing plate. The contributions to WP2 are focused on the layer deposition technology development as part of the basic WBG technology development of the project.

CONTACT

Sindlhauser Materials GmbH

Daimlerstr. 68

87437 Kempten, Germany

SET Power Systems GmbH

We are a joint venture and part of the AVL group. There are good reasons for this. We transfer the key market knowledge of AVL to inverter test technology. And we transfer the knowledge of SET GmbH from the world of aviation to the automotive world: Comprehensive testing without having to “fly” immediately.

The vertical range of manufacture is great, since the electronic planning, the electrical planning and the mechanical control cabinet planning are carried out in-house, and, except for the board production and the mechanical production, the assembly is completely realized in-house.

Our technology originates from our own house and has established itself on the market 15 years ago.

COMPANY DESCRIPTION

SET Power Systems GmbH was founded in 2012 as a medium-sized company in Wangen and currently employs (as of July 2018) approximately 67 employees at the company headquarters in Wangen.

The SPS develops, markets, sells and produces electric motor emulations in a wide range of electrical power and with high-resolution real-time characteristics.

Users who make or use DC power sources and converters to power electric motors can thus test and optimize this combination of power source and motor supply without the use of real motors and powertrains.

The unique selling proposition is the spectrum of electrical power and the high temporal resolution of the real-time characteristic, which enables a quasi-continuous, analogue simulation of the motor without digital artifacts on the time scale of the inverter.

The core competence consists of the fast power electronics, the fast control of the power electronics, the fast measurement technology of the electrical signals and the simulation of the motor on this time scale. Furthermore, an agile approach and the creation of rapid functional patterns as essential skills are sought.

ROLE & KEY CONTRIBUTION

In particular, SET Power Systems GmbH deals with key issues such as the specification and design of high-performance DC / DC and AC / DC modules as well as topologies with SiC (high voltage) and GaN (low and medium voltage) semiconductors , which are a fundamental basis of the described test systems.

Further priorities are the development of concepts for:

• significantly lower power loss (30% less than today)

• appropriate cooling processes and heat sink connections to reduce common-mode currents and potential shifts between the test specimen and the test system

• Inverters, which are more cost-effective, although the built-in SiC components are more expensive than current Si-based components. This is possible thanks to other components of the test system (e.g., passive components and DC intermediate circuit capacitors).

CONTACT

SET Power Systems GmbH

August-Braun-Straße 3

88239 Wangen/Allgäu, Germany

Ibermática

Ibermática is one of the main IT service companies on the Spanish market. Its activity is focused on the following areas: consultancy, infrastructure services, information system integration, outsourcing and business integrated solutions. It also offers specific vertical solutions to the main markets (Finance, Insurance, Industry Manufacturing, Services, Telecommunications & Media, Healthcare, Utilities and Public Administration).

COMPANY DESCRIPTION

Ibermática completes its offer with technological solutions such as Business Intelligence, ERP&CRM, business process management (BPM), portals and digital business, document management, Social Business, human capital management (HCM), mobility, accessibility, security and artificial intelligence, as well as Cloud Computing services.

At present, it brings together 3,100 professionals, distributed around more than 20 offices in different countries, and has a turnover of 225 million euros.

ROLE & KEY CONTRIBUTION

IBERMATICA is basically involved in the Use-case on Automotive industry, its main role is focused on data analytics and big data.

CONTACT

Ibermátic SA

Paseo Mikeletegi 5

20009 San Sebastian, Spain

ENCOPIM, S.L.

ENCOPIM is a SME based in Barcelona (SPAIN) grounded in 1995 by 2 entrepreneurs. Nowadays ENCOPIM is 100% dedicated to the design and manufacture of state of the art test rigs, which are custom-made for the needs of the customer (usually within the Automotive Sector).

COMPANY DESCRIPTION

ENCOPIM, S.L. is a leading company in development, manufacturing, installation, commissioning and later servicing of turnkey testing equipment. In the automotive sector ENCOPIM supplies customers with servo-pneumatic, servo-electric and servo-hydraulic testing systems, such as passive safety equipment (e.g. impact test machines) or powertrain test rigs (e.g. for gearboxes or shafts). As a result of deep specialization and continued investment on R&D for many years, ENCOPIM has its own technology in control electronics, software and mechanics, which allows supplying innovative solutions with high added value. ENCOPIM: BRAINCRAFTED TEST RIGS.

ROLE & KEY CONTRIBUTION

ENCOPIM will design and manufacture a specially designed an e-machines test rig tailor-made to the specific needs of our partners in order to validate the various developments achieved in terms of energy efficiency, NVH, thermal optimization, etc. of the powertrain system. Therefore, ENCOPIM will collaborate with other partners in defining the tests necessary for the powertrain validation and with the specially made test rig will help to validate the system.

We can communicate via CAN bus with other partners’ systems to, for instance, receive setpoints for velocity at the wheels or communicate with the powertrain’s ECU. This capability of communication with external systems of our SCP-NET controller will enable the simulation of actual driving conditions in a real in-wheel E-motor application.

CONTACT

ENCOPIM, S.L.

Carretera de Santiga 104

08291 Ripollet (Barcelona), Spain

TU Darmstadt (TUDA)

Since its foundation in 1877, TU Darmstadt has played its part in addressing the urgent issues of the future with pioneering achievements and outstanding research and teaching. TU Darmstadt focusses on selected, highly relevant problem areas. Technology is at the heart of all our disciplines at TU Darmstadt. The Natural Sciences as well as Social Sciences and Humanities cooperate closely with Engineering.

COMPANY DESCRIPTION:

Within HiPERFORM TU Darmstadt will be represented by the institute for Power Electronics and Control of Drives (Prof. Dr.-Ing. Gerd Griepentrog). The institute has commemorated its 50th anniversary in 2013 and was the first Power Electronics institute in Germany. Among other topics, the institute pioneered HVDC power transmission, field-oriented control and investigated the influence of CMV on electric machines. Today the scientific work of the institute is focussed on the interaction of power electronics and the power supply and energy efficient electrical drives.

ROLE & KEY CONTRIBUTION:

The main contribution of TU Darmstadt is the development of optimal model-based control strategies for the power electronics components and test systems considered in the use cases of HiPERFORM. TUDA will examine the utilization of model-predictive control strategies, systematically taking into account the system constraints and nonlinearities. A further focus will lie on the efficient real-time capable implementation of the control strategies utilizing FPGA or SystemOnChip-Platforms.

CONTACT

TU Darmstadt

Karolinenplatz 5

64289, Darmstadt, Germany

Nano Design s.r.o

NanoDesign is a spin-off company, founded in 2007 by a group of specialists in field of precise measurement in bioelectronics.

COMPANY DESCRIPTION

Today it is research and development company composed of 7 full-time research workers strengthened yearly by extra 3-4 master and PhD degree students. Several research projects are being resolved yearly, mostly in field of design of precise measurement devices, measurement modules for testing and characterization. High precision bioelectronics devices and measurement test stations were developed. The measurement devices (TDR, UIS) facilitate selective research tasks in EU projects with focus on new devices and technologies (GaN, Si).

ROLE & KEY CONTRIBUTION

Contribution to WP2 - modification of UIS tester especially for testing of SiC, reliability testing of SiC and GaN devices.

CONTACT

NANO DESIGN SRO

Drotarskacesta 6385 19A

81104 Bratislava, Slovakia

THIS PROJECT HAS RECEIVED FUNDING FROM THE ECSEL JOINT UNDERTAKING (JU)

UNDER GRANT AGREEMENT NO 783174.

THE JU RECEIVES SUPPORT FROM THE EUROPEAN UNION’S HORIZON 2020 RESEARCH AND INOVATION PROGRAMME AND AUSTRIA, SPAIN, BELGIUM, GERMANY, SLOVAKIA, ITALY, NETHERLANDS, SLOVENIA.

| This project is co-funded by the Ministry of Education, Universities and Research in Italy (www.istruzione.it) |  |

| This project is co-funded by Netherlands Enterprise Agency (www.english.rvo.nl) |  |

| This project is co-funded by The Ministry of Education, Science, Research and Sport of the Slovak Republic. (www.minedu.sk) |  |

| This Project is co-funded by the Federal Ministry of Education and Research of Germany. (www.bmbf.de) |  |

| This Project is co-funded by MINETUR in Spain. (www.minetur.es) |  |

| This project is co-funded by the agency for Innovation by Science and Technology in Belgium. (www.iwt.be) |  |

| This project is co-funded by the Ministry of Economic Development and Technology of the Republic of Slovenia. (www.mgrt.gov.si) |

|